$4,900.00

PowerPinner® 7310 Heavy Duty – Portable CD Hand Welder

Fasten Foil Faced Insulation With Precision Even On Pre-Painted Metal

With a series of innovative and practical features packed into a compact yet rugged unit, the PowerPinner 7310 brings a lot to the table. The 7310 comes standard with an intuitive digital touchscreen that any operator can utilize for quick setup and consistent welding. With dual input voltages the 7310 allows for the operator to pick up and go regardless of the power compatability. Weld 10-14 gauge Weld Pins with this versitile piece of equipment!

With a series of innovative and practical features packed into a compact yet rugged unit, the PowerPinner 7310 brings a lot to the table. The 7310 comes standard with an intuitive digital touchscreen that any operator can utilize for quick setup and consistent welding. With dual input voltages the 7310 allows for the operator to pick up and go regardless of the power compatability. Weld 10-14 gauge Weld Pins with this versitile piece of equipment!

Features Include:

Portable

An advanced lightweight design, with handle, makes maneuvering the 18 lbs. power unit very easy.

High Output Duty Cycle

With the capability of 30 pins per minute, this unit is made for true production application.

Input Voltage –

110 VAC at 50/60Hz 10 Amp Circuit

220 VAC at 50/60 Hz 5 Amp Circuit

Cables

Gun – 21 feet, #4 weld cable and #18/2 control cable

Ground – 15 feet, #4 weld cable, terminating in a variable option ground clamp

LINKS:

https://www.gripnail.com/media/pdfs/sales-lit/gripnail-powerpinner-7310-digital.pdf

Gripnail Cup Head Weld Pins

For peak performance, it is highly recommended using GRIPNAIL’s full line of Cup Head Weld Pins. Available in three different cap sizes, multiple shank diameters, and a variety of lengths.

Additional Features

For the first time ever you can now weld insulation onto pre-painted metal without any hassle!

Intuitive Touchscreen Interface –

An easy-to-use Touchscreen interface offers preset values for fast, accurate, and repeatable weld settings. Operation specific information and diagnostic indicators are also included should troubleshooting becomes required.

Set-Point Discharge –

The unit will discharge directly to a new set point without needing to discharge completely. This allows optimization of weld quality without sacrificing efficiency.

Input Voltage – A plug-and-play system allows the use of 120 or 240 input voltages without the need to re-tap the unit. Built-in low input voltage capability enables applications with longer extension cords.

Thermal and Voltage Protection –

Thermal and Voltage indicators on the front screen of the unit notify operators of overheating or poor input power supply situations.

Rigid Internal Construction –

The unit is internally designed as a rigid construction, connecting all the internal components to the front and rear panels. This minimizes the opportunity of the components being affected by rigorous environments normally found in common applications.

Specialized GRIPNAIL Weld Gun –

The GRIPNAIL Pistol Grip Weld Gun has a preset spring which applies the precise amount of pressure required to perfectly set a Cup Head Weld Pin. This feature is set and quality checked during its manufacturing and cannot be altered.

The weld tip uses a strong magnet to secure the Cup Head Weld Pin during application.

Optional: A non-conductive shield is available for applications using foil faced insulation. This compresses the foil face around the weld tip and prevents arcing or burn marks on the face of the insulation.

Variable Quick Change Ground Clamp System

A. C-Clamp

Used For: Non-Painted Material – Low Output Volume

B. Squeeze Clamp

Quicker and more ergonomic than the C-Clamp to keep your production moving more efficiently.

Used For: Non-Painted Material – Mid – High Output Volume

C. Elite Clamp

A specialized Squeeze Clamp for a superior ground connection on Pre-Painted surfaces.

A prefabricated hole is required. Low – High Output Volume

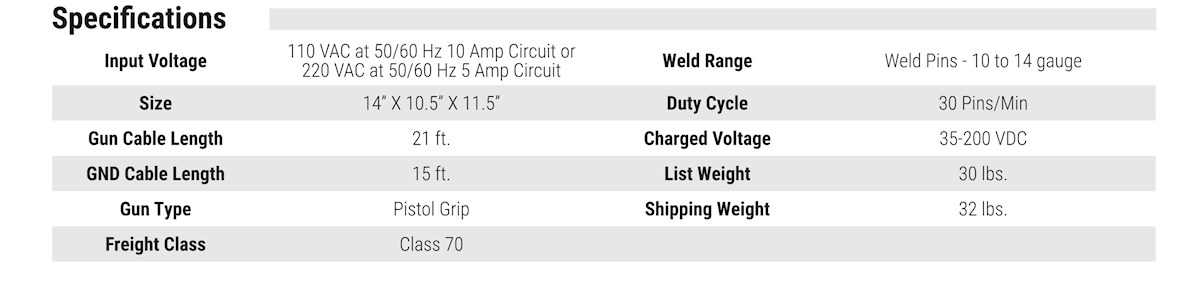

Specifications