PowerPinner® 7105HS High Speed – Moving Head Duct Lining Welder

Continuously Line 5-Foot Wide Ductwork

The new PowerPinner 7105HS boasts the quickest cycle time and most reliable welds available. Thanks to a technological breakthrough, the 7105HS high speed welder is built with the same high quality materials you have come to expect form Gripnail. Functioning without any mechanical reeds switches, the 7105HS on-board computer has been turbo-charged for peak performance. The new Programmable Logic Controller produces welding speeds never before seen without sacrificing welding quality.

Contractors who regularly line large fittings and straight duct will find the convenience of the 7105HS speeds their assembly and reduces fabrication costs. The weld head travels a full 60 inches for lining 5-foot wide duct. The head is moved with a multi-position extension arm and glides on specially designed bearings, while all wires are reinforced in a wire sleeve and securely housed in an energy chain.

Features Include:

Cycle Time

At 83 cycles per minute, the new PLC reaches coil line speeds.*

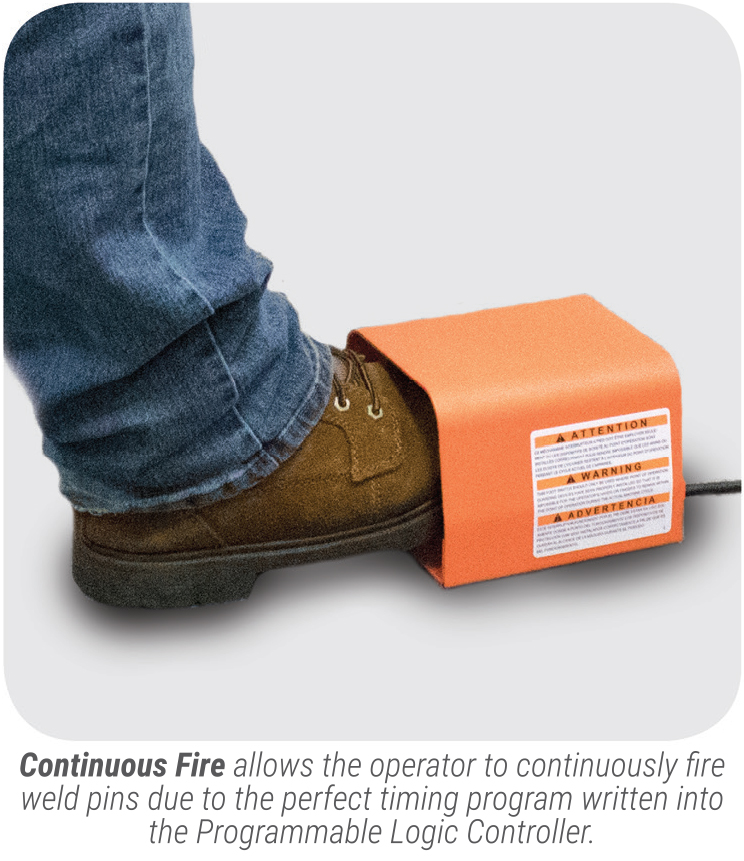

Continuous Fire

Depressing the ergonomic foot pedal while the Continuous Fire switch is on allows the operator to continuously weld pins without having to lift their foot off the pedal.

High Capacity, Split Weld Pin Track System

Upwards of 25 pins are available from the lower track before additional pins are speed loaded from the upper track.

High Output Transformer

Produces the strongest possible welds for 1/2″ all the way to full” pins fastened to 16-26 gauge sheet metal.

Links:

gripnail-powerpinner-7105hs-high-speed-moving-head-welder

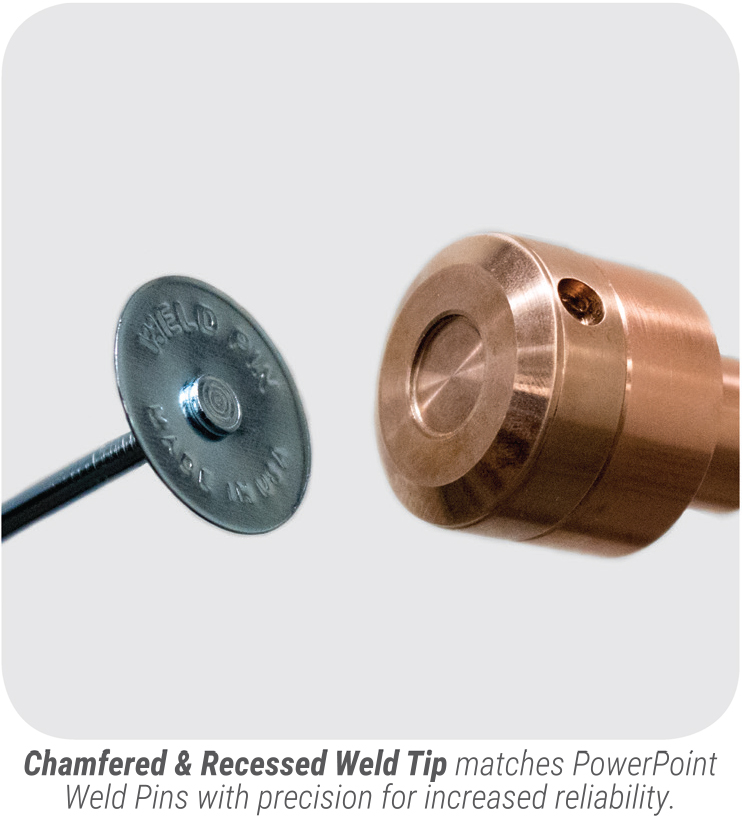

PowerPoint® Weld Pins

For peak performance, it is highly recommended using Gripnail’s wide range of PowerPoint Weld Pins. Each point is precisely formed to provide optimum electrical resistance.

A PowerPoint Weld Pin permanently attaches insulation to galvanized steel in fabrication of HVAC duct work and withstands a tensile pull of at least 120 pounds in sheet metal.

Additional Features

Programmable Logic Controller

Inside the control box is a PLC, which has been programmed here in the USA, to coordinate welding and machine functions resulting in the fastest and most perfected weld every time. Machine operators only need to increase the weld setting for longer pins or thicker sheet metal, and the PLC will set the dwell time and coordinated the feed cycle. Minimal operator training is needed for this machine which means maximum flexibility. The PLC even has a diagnostic screens should a machine element require attention.

The PLC allows for minimum operator intervention during setup or job changes, all while producing maximum performance at industry leading speeds.

Chamfered & recessed Weld Tip

The magnetic upper weld tip is specially designed with a chamfered ege and recessed center to optimize the weld quality of PowerPoint Weld Pins. The unique characteristics of the PowerPoint weld pin’s noninvasive protruding shank captures and centers the weld pin to ensure consistent loading, while the beveled retaining cap prevents it from shifting off the weld tip when the pin is being set through the insulation. Although the PowerPinner 7105HS works with a variety of weld pins, using our PowerPoint’s precision manufacturing process assures a trouble free operation with the best quality weld possible.

Quick Change Weld Tips

Upper and lower weld tips can be replaced in seconds. The lower weld tip is purposefully off centered so that once an area is worn down, the operator can make a small roational adjustment and use a new part of the weld tip for extended product life.

Double-Acting Load Cylinder

To keep up with the intense speeds of the PLC, double-acting load cylinders are standard on every machine. This ensures that each Weld Pin is loaded at maximum speeds without the danger of a component collision potentially possible with single-acting cylinders, which may lag due to its dependence on spring tension.

Simplified Controls

A single weld-setting switch controls the weld time while the PLC optimizes the dwell time. The other controls are a “continuous fire” on/off switch and a feeder bowl speed control The PowerPinner 7105HS also comes with a LED voltage readout which informs the operator of a low voltage situation which an affect the integrity of the weld.

Safety – A high visibility power switch comes standard with a simple to use Lockout/Tagout features.

NEMA® Type 12 Electrical Enclosures

To protect vital components from the rigor of most manufacturing environment,s every electrical enclosure is rated to the National Electrical Manufacturers Association’s Type 12 standards. This protects your investment form dust, debris, adhesive remnants and oil vapor from reaching operation critical components.

Large Capacity Feeder Bowl

The large capacity feeder bowl can accommodate a full range of pins from half inch to 2 inch and operators can control the pin feed speed on the control box.

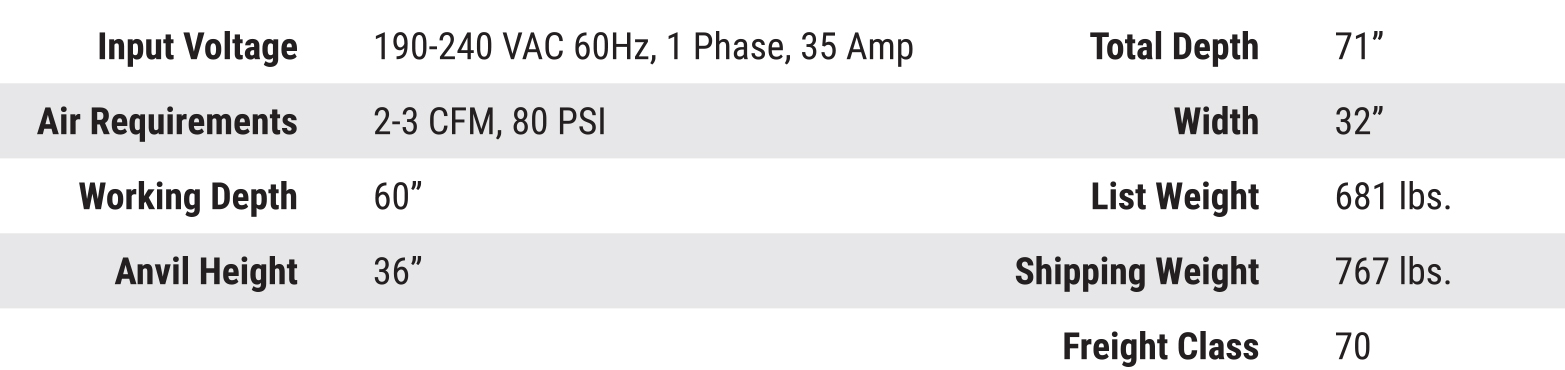

Specifications